REMEMBER, CONSTRUCTION AND DESIGN DOES MAKE A DIFFERENCE! We are the only Manufacturer in the USA that produces a Heat Exchanger designed for: (RTT) Rapid Thermal Transfer TM using Axis Point Technology (APT) TM . This is where the exhaust gases from a Combustable Engine reach all the Spiral Tubing that carries the water heating it at all Axis Points of the tubing simultaneously .

The Industry's Conventional Standard all use either Layered Spirally Wound Tubing on each other where Heat Conductance is lost between the Layers of Tubing.

The other method uses "TUBE IN A SHELL" Straight Tubes going through a Chamber (Pipe) where the Void for the water is greater and the Volume & Number of Conductance Tubes that carry the Exhaust gases are too few. ALSO, "TUBE IN A SHELL" CAN DAMAGE YOUR TRUCK MOUNTS ENGINE BECAUSE OF THE BACK-UP PRESSURE. THE ENGINE'S EXHAUST ENTERS A SMALL COMPARTMENT CHAMBER WHERE IT IS FORCED TO ENTER SMALL ELONGATED CONDUCTANCE TUBES CAUSING A BACK-UP PRESSURE ISSUE.

This is why the Industry Standard is less effective and inefficient in Thermal Transfer into the water.

As a result of our NEW Patented All Stainless Steel Heat Exchanger is internally designed to Transfer Exhaust Heat Quicker (Within 2 Minutes) and more efficiently than any other competition Heater.....and with Minimal Back-up Pressure to make your Engine Last a Long Time.

This means Continuous Hotter Water Lasting Longer up to 230 degrees F plus during the most soiled carpet cleaning conditions. Great for Pressure Washing where High Pressure & Temperature is needed.

Typical "BAD DESIGN" of a "TUBE IN A SHELL" Engine's Exhaust Enters " TINY CHAMBER " (Here)

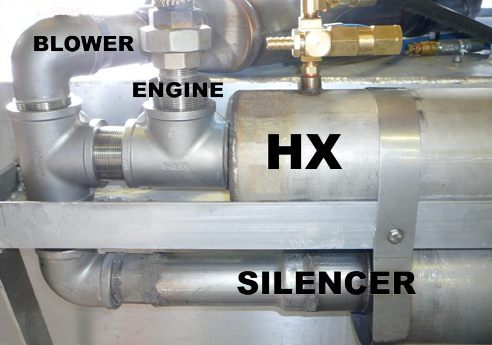

Large Compartment allows "FREE FLOW" with Minimal Back Up Pressure. "Your Engine will Love you for it."

FREE FLOW OF EXHAUST GASES